ITEM | MH-500 |

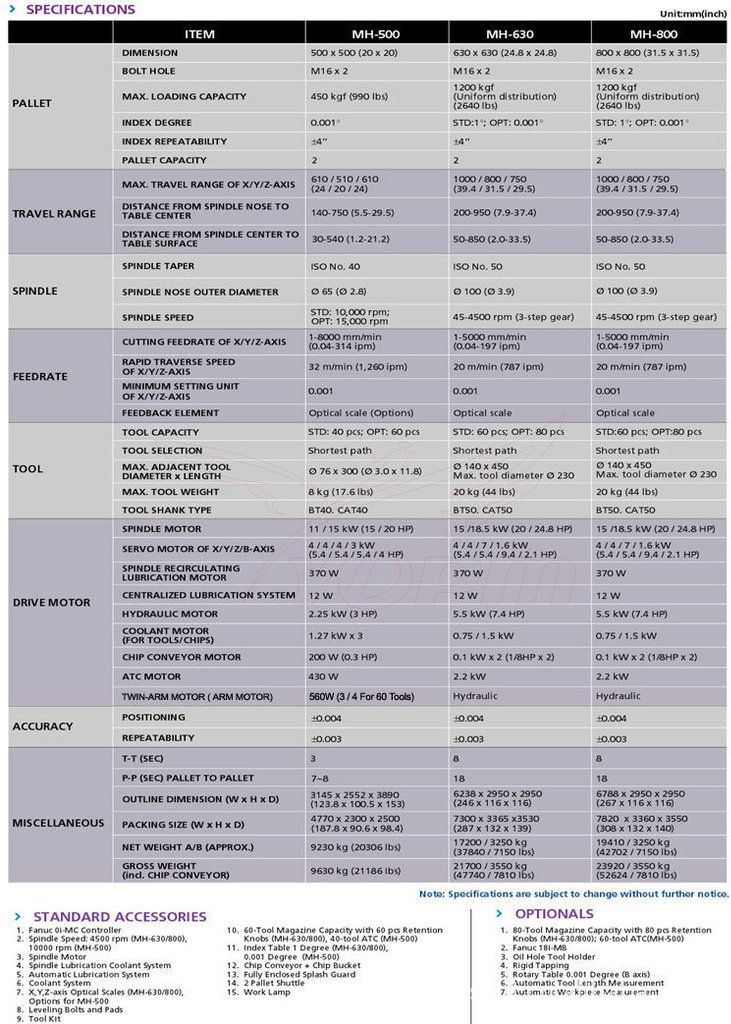

Pallet | Dimensions | 500 × 500 (20 × 20) |

Bolt hole | M16 × 2 |

Max. loading capacity | 450 kg (990 lbs) |

B minimum indexing (degree) | 0.001° |

Index repeatability | ± 4” |

Pallet capacity | 2 |

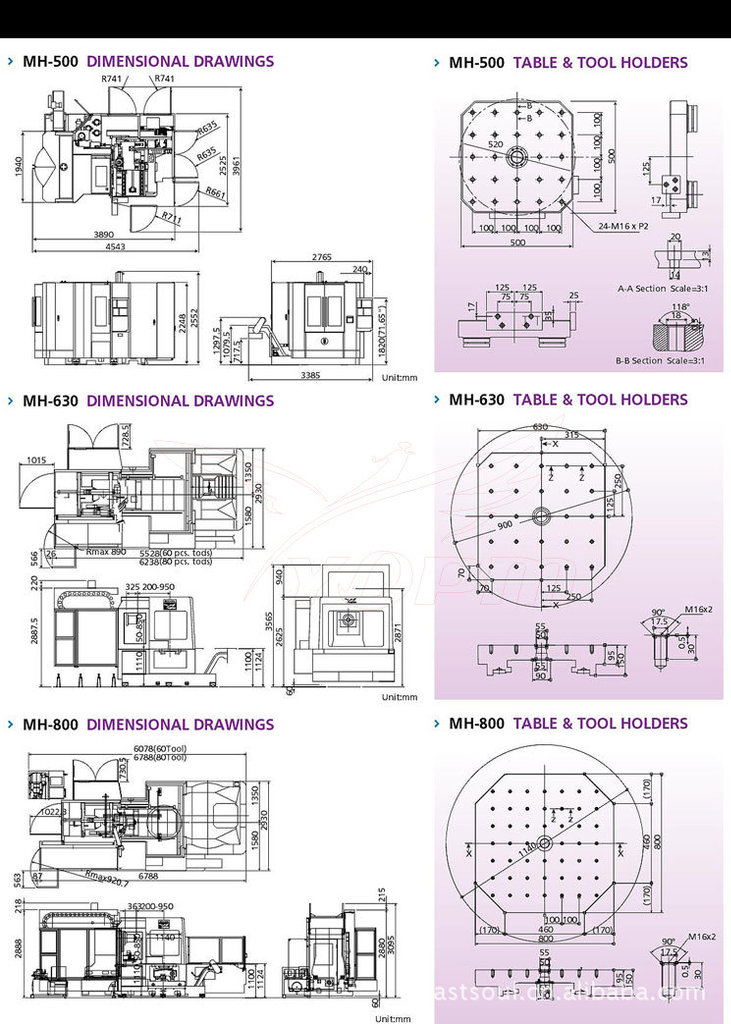

Travel Range | Max. travel range of X/Y/Z-axis | 610×510×610 (24×20×24) |

Distance from spindle nose to table center | 140~750 (5.5-29.5) |

Distance from spindle center to table surface | 30~540 (1.2-21.2) |

Spindle | Spindle taper | ISO No. 40 |

Spindle nose outer diameter | Ø 65 (Ø 2.8) |

Spindle speed | STD: 10,000 rpm; OPT: 15,000 rpm |

Feedrate | Cutting feedrate of X/Y/Z-axis | 1~-8000 mm / min (0.04~314 ipm) |

Rapid traverse speed of X/Y/Z-axis | 32 m / min (1,260 ipm) |

Minimum setting unit of X/Y/Z-axis | 0.001 |

Feedback element | Optical scale (options) |

Tool | Tool capacity | STD: 40 pcs; OPT: 60 pcs |

Tool selection | Shortest path |

Max. adjacent tool diameter × length | Ø 76 × 300 (Ø 3.0 × 11.8) |

Max. tool weight | 7 kg (15.4 lbs) |

Tool shank type | BT40. CAT40. |

Drive Motor | Spindle motor | 11/15 kW (15/20 HP) |

Servo motor of X/Y/Z/B-axis | 4 / 4 / 4 / 3 kW (5.4 / 5.4 / 5.4 / 4 HP) |

Spindle recirculating lubrication motor | 120 W+180 W (1/6HP+1/4HP) |

Centralized lubrication system | 12 W |

Hydraulic motor | 2.25 kW (3 HP) |

Coolant motor (for tools/chips) | 1.27kW × 3 |

Chip conveyor motor | 200 W (0.3 HP) |

ATC motor | 430 W |

Chain type chip conveyor + Chip bucket | 560 W |

Accuracy | Positioning | ± 0.004 |

Repeatability | ± 0.003 |

| Miscellaneous | T-T (sec) | 3 |

P-P (sec) pallet to pallet | 7~8 |

Outline dimensions (W × H × D) | 3145 × 2552 × 3890 (123.8 × 100.5 × 153) |

Packing size (W × H × D) | 4770 × 2300 × 2500 (187.8 × 90.6 × 98.4) |

Net weight (approx.) w/80-tool | 9230 kg (20306 lbs) |

Gross weight (approx.) w/80-tool | 9630 kg (21186 Ibs) |